As market demand continues to increase, more and more projects use LED displays as the first choice for advertising. In the environment of market demand and industry competition, major manufacturers have begun to develop ultra-thin, energy-saving, and lightweight products in addition to improving product quality and services. Today I will mainly introduce the advantages and disadvantages of Slim LED screens, as well as the market development trends.

The advantages of Slim LED display are as follows:

1. Lightweight: Ordinary LED screen boxes use iron boxes. In order to reduce weight, Slim LED displays are more likely to use aluminum boxes, which have the advantages of good toughness, lightweight, and anti-corrosion. The weight of ordinary LED screens is about 40 kg/square meter, and the weight of the Slim LED display is reduced to 24 kg/square meter.

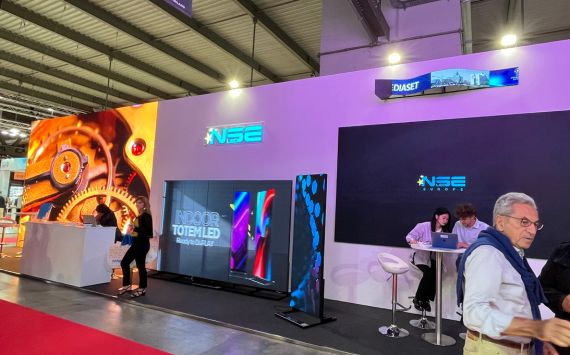

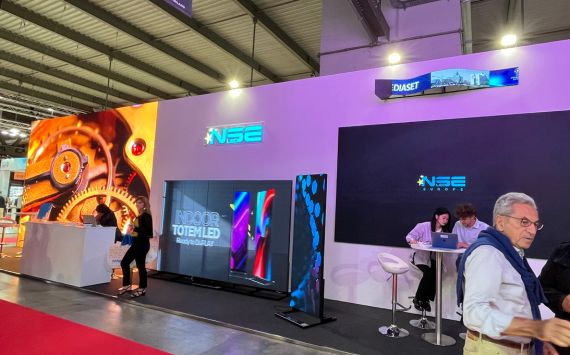

2. Thin thickness: The thickness of ordinary LED screens is about 200mm ~ 300mm, the thickness of Slim LED display can be 100mm ~ 150mm, and the NSE slim poster series is only 450mm thick.

3. Convenient transportation: Because Slim LED displays are light in weight, they are easy to transport and can save transportation costs.

4. Convenient installation: The installation speed is much improved, and can save the installation space as well.

5. Reduce installation costs: Ordinary LED screens require more than 2 people to install, while Slim LED displays can be moved and installed by one person.

6. Easy maintenance: Ordinary LED screens are maintained through rear maintenance channels, while Slim LED displays can be maintained through front and rear maintenance methods to improve maintenance efficiency.

The advantages of Slim LED screen have been introduced before. Now let’s talk about the disadvantages of Slim LED screens:

1. Not easy to dissipate heat: The thinner thickness of the Slim LED screen is not conducive to the air circulation inside, making it difficult to dissipate heat internally. The heat can only be dissipated through the aluminum shell to reduce the heat of the screen.

2. The display size is limited: Slim LED screens are not suitable for custom-made large sizes, which will affect the stability and safety of the screen.

3. High requirements on the external environment: Slim LED screens are easily affected by external impacts or bad weather, causing screen damage or failure to display properly.

4. High production process requirements: Slim LED screens have very high requirements for factory technicians. They require experienced technicians to design and produce. Various problems need to be solved during the production process. Not every LED display manufacturer can Can produce ultra-thin screens.

How to maintain the Slim screen?

1. Keep the humidity of the environment where the Slim screen is used, and do not let anything with moisture enter your Slim screen. Applying power to an outdoor Slim screen that contains humidity will cause corrosion of components, thereby causing damage to the display.

2. The Slim screen has a close relationship with our users, and it is very necessary to do a good job in cleaning and maintenance. Slim screens are prone to getting dirty when exposed to wind, sun, dust, etc. in the outdoor environment for a long time. After a period of time, there will definitely be dust on the screen. This needs to be cleaned in time to prevent dust from covering the surface for a long time and affecting the viewing effect.

3. To avoid possible problems, we can choose passive protection and active protection. Try to keep items that may cause damage to the Slim screen as far away from the screen as possible. When cleaning the Slim screen, wipe it as gently as possible. The possibility of injury is minimized.

4. It is strictly forbidden to allow water, iron powder, and other metal objects that are easily conducive to enter the Slim screen. Slim screen should be placed in a low-dust environment as much as possible. Large dust will affect the display effect, and too much dust will cause damage to the circuit. If water enters due to various reasons, please cut off the power immediately and contact maintenance personnel until the display panel inside the screen is dry before use.

5. The power supply is required to be stable and the grounding protection is good. Do not use it under harsh natural conditions, especially strong lightning weather.

6. The switching sequence of the Slim screen will also have an impact: first, the control computer must be turned on before turning on the Slim screen. This is when it is turned on. When shutting down, first turn off the Slim screen and then turn off the computer.

The Slim LED has gone through a period of rapid development for many years, with continuous innovation in product technology and the application of raw materials. The integration of Slim LED with the market has been greatly improved. The functions of products are gradually improving in practical application environments. Slim LED and energy-saving LED screens will be more and more needed in the future market.

English / America

English / America 简体中文 / 中国

简体中文 / 中国 Español / España

Español / España Italiano / Italia

Italiano / Italia